Table of Contents

ToggleWhat Is a BIM Execution Plan (BEP)?

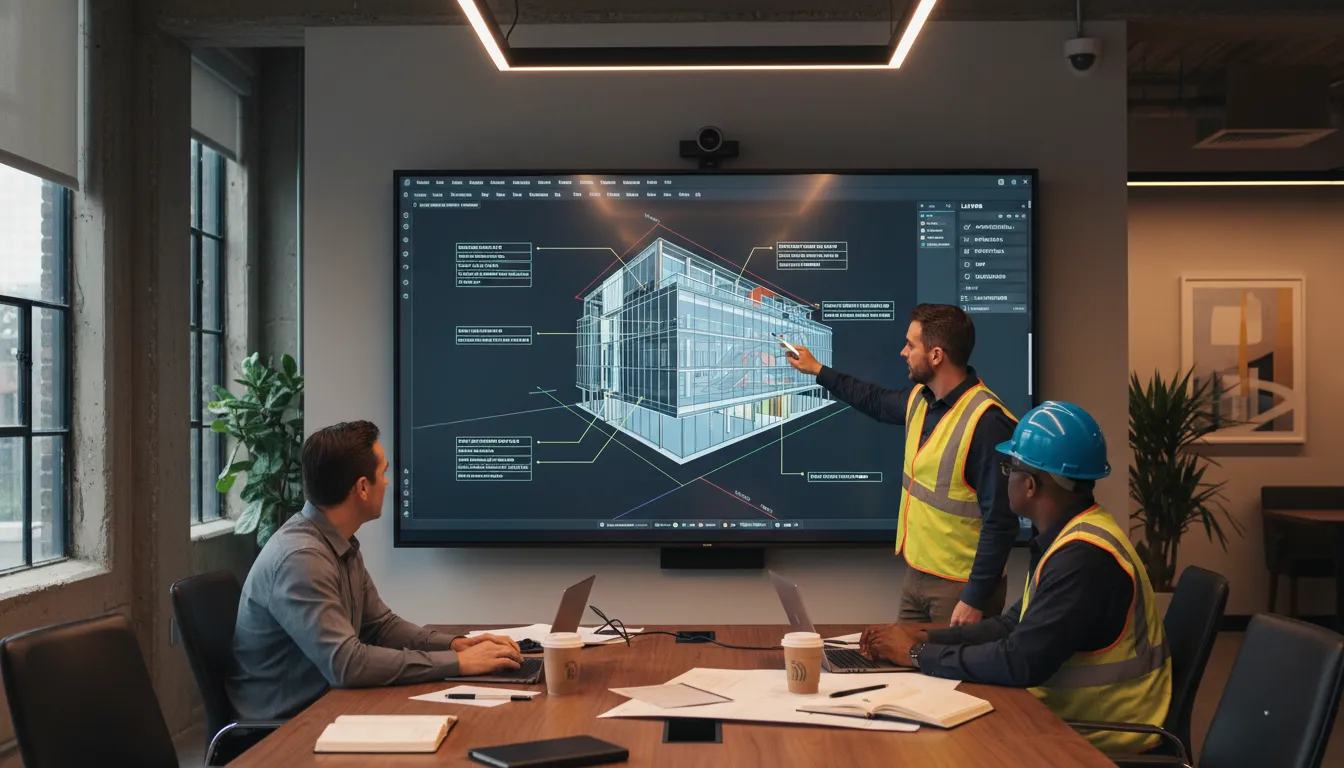

The BIM Execution Plan is a formal document created at the onset of a project to outline how BIM processes, data, and models will be developed, shared, and managed across teams. It sets the “rules of engagement” for all project participants—architects, engineers, consultants, and contractors.

For BIM managers, this plan is more than an administrative exercise. It’s a project’s **digital constitution**—standardizing workflows, defining deliverables, and ensuring consistency in information exchange.

Primary Purpose of a BEP

- Define project BIM goals and uses (design coordination, estimation, facilities management, etc.)

- Establish project standards and naming conventions

- Clarify responsibilities and the chain of approval among stakeholders

- Specify software platforms and data exchange formats

- Set quality control and model validation rules

Without a clear BEP, teams often face duplicated work, inconsistent file names, mismatched coordinate systems, and ultimately, Schedule creep caused by repeated coordination issues.

Types of BEP: Pre‑Contract and Post‑Contract

According to best practices, two types of BEPs guide project stages:

- Pre‑Contract BEP: Prepared before the project begins, often to demonstrate a contractor’s understanding of the BIM deliverables outlined in the Employer’s Information Requirements (EIR). This document sets your intent and technical capability.

- Post‑Contract BEP: Developed after contracts are awarded. This is a detailed, project‑specific guide defining model sharing, versioning, collaboration platforms, and responsibility matrices across disciplines.

Many GCs and BIM coordinators find that the pre‑contract BEP serves as a proposal tool, while the post‑contract BEP functions as the operational roadmap.

Creating a BEP Template That Works

A well‑structured template ensures flexibility and standardization, so your BEP can evolve with each project. The most effective templates include:

- Project objectives and BIM uses

- Roles and responsibilities matrix

- Information exchange protocols (file formats, CDE workflows)

- Model structure and Level of Development (LOD) definitions

- Coordination and quality control schedule

- Model submission and approval process

- Change management and version tracking

These sections not only ensure continuity but also make it easier for new team members to understand your project’s BIM environment quickly.

Need a Customized BEP for Your Construction Project?

Let Design Sync Studio help you create a comprehensive BIM Execution Plan that improves efficiency, clarifies responsibilities, and eliminates costly coordination errors.

📞 Call +1‑215‑995‑4450

💬 or Contact us online to discuss your project today.

Level of Development (LOD) in BEP

Level of Development, or LOD, is the backbone of BIM detail accuracy. The BEP defines the minimum LOD standards at each project stage—from conceptual to as‑built.

- LOD 100: Conceptual—basic massing models showing area, height, and orientation.

- LOD 200: Approximate—generic systems and elements with estimated quantities.

- LOD 300: Precise geometry matching design intent, ready for interdisciplinary coordination.

- LOD 350: Detailed connectivity between interacting systems (e.g., MEP & Structural).

- LOD 400: Fabrication‑ready information including manufacturer‑specific components.

- LOD 500: As‑built condition for facility operation and maintenance.

Well‑defined LOD stages prevent unnecessary modeling effort and help each trade deliver accurate data within scope. Our 3D modeling and BIM coordination services are tailored around this very principle—delivering clarity and constructability.

Naming Conventions and File Management in a BEP

A standardized naming protocol ensures that every model, file, and sheet is easily identifiable. It’s especially vital for multidisciplinary projects where multiple file versions are exchanged daily between firms and consultants.

A general naming formula often used is:

ProjectCode_Originator_Volume_Level_Type_Role_Number

Example: ABC_ARC_V01_L01_M3D_AR_010.rvt

ABC Project (Architecture Model, Volume 1, Level 1, BIM 3D, Architect Discipline).

Consistency like this minimizes the risk of version confusion and promotes clean data exchange through the Common Data Environment (CDE). It also becomes invaluable during permit expediting and quality assurance stages.

Integration of BEP with Project Estimation and Coordination

A mature BEP doesn’t stop at design—its benefits continue through procurement and cost management. Accurate quantity take‑offs depend on uniform model classifications and consistent geometry.

Our construction estimating services rely on BEPs with established LOD and coding systems, ensuring that every modeled component corresponds directly to a cost line item.

The BEP also serves as the “roadmap” during coordination meetings where clashes are tested, issues tracked, and design updates verified within the federated BIM model.

Common BEP Challenges and How to Overcome Them

- Unclear Ownership: Define who authors, reviews, and approves each model package.

- Over‑Detailed Models: Establish appropriate LOD to prevent wasteful over‑modeling.

- Inconsistent File Naming: Enforce automated checking tools for protocol compliance.

- Late Model Coordination: Schedule regular BIM coordination sessions to maintain alignment.

- Poor Communication: Use a shared CDE and version control log accessible to all key stakeholders.

Each of these pitfalls can be controlled through a robust BEP—an instrument that transforms digital construction from disjointed to data‑driven.

Role of Design Sync Studio in Developing BEPs

Our BIM experts collaborate directly with your in‑house teams or subcontractors to prepare both pre‑contract and post‑contract BEPs tailored to your workflow. From file setup and naming structure to coordination templates and reporting dashboards, we implement a framework that your entire organization can reuse across projects.

Combined with our architectural design services and data‑ready BIM workflows, Design Sync Studio ensures your BIM execution plan aligns with both client expectations and construction deliverables.

Conclusion

A well‑crafted BIM Execution Plan (BEP) is not just a document—it’s a living agreement between all project participants. It protects quality, defines accountability, and keeps data moving smoothly throughout the lifecycle of a building. For BIM managers and general contractors, investing time in your BEP means fewer change orders, smoother approval cycles, and measurable cost savings.

With Design Sync Studio, you gain a technology‑driven partner ready to set up your BIM standards, develop your BEP, and coordinate your models with clarity and precision.